Exploring the Process of Custom Thai Silk Production

Thailand is renowned for its exquisite silk production, with a long history of creating some of the finest silk fabrics in the world. Custom Thai silk production is a meticulous process that involves skilled artisans and traditional techniques passed down through generations. From the selection of the finest silk threads to the intricate weaving and dyeing processes, every step in the production of custom Thai silk is carefully executed to create luxurious and unique fabrics.

The journey of custom Thai silk production begins with the selection of the finest silk threads. Thai silk is made from the cocoons of the silkworm, which are carefully harvested and processed to extract the delicate silk fibers. These fibers are then spun into threads, which are meticulously inspected for quality and consistency. Only the finest threads are selected for custom Thai silk production, ensuring that the final fabric is of the highest quality.

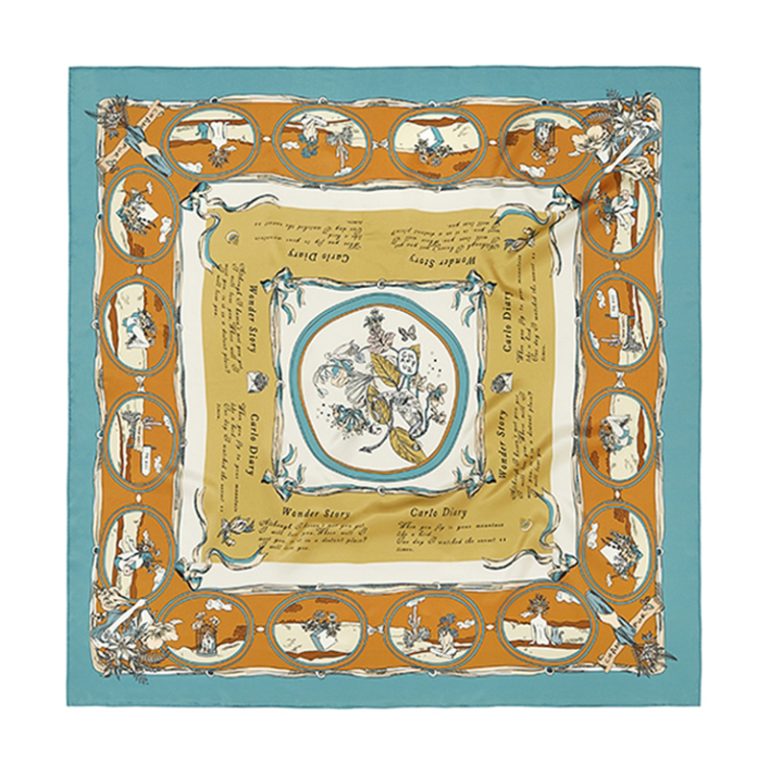

Once the silk threads have been selected, they are ready to be woven into fabric. Traditional Thai silk weaving techniques involve intricate patterns and designs that are passed down through generations. Skilled artisans use handlooms to carefully weave the silk threads together, creating beautiful and unique fabrics that showcase the artistry and craftsmanship of Thai silk production. Each custom Thai silk fabric is a work of art, with intricate patterns and vibrant colors that reflect the rich cultural heritage of Thailand.

After the fabric has been woven, it is ready to be dyed. Thai silk is known for its vibrant colors and rich hues, which are achieved through a meticulous dyeing process. Natural dyes made from plants, fruits, and insects are used to create a wide range of colors, from deep blues and purples to bright reds and oranges. Skilled dyers carefully mix and apply the dyes to the fabric, ensuring that each custom Thai silk piece is unique and vibrant.

Once the fabric has been dyed, it is ready to be finished. Custom Thai silk production involves a variety of finishing techniques, including washing, pressing, and steaming. These processes help to enhance the luster and softness of the silk fabric, creating a luxurious and elegant finish. Skilled artisans carefully inspect each piece of custom Thai silk to ensure that it meets the highest standards of quality and craftsmanship.

Custom Thai silk production is a labor-intensive process that requires skill, patience, and attention to detail. From the selection of the finest silk threads to the intricate weaving and dyeing processes, every step in the production of custom Thai silk is carefully executed to create luxurious and unique fabrics. The result is a beautiful and timeless fabric that showcases the artistry and craftsmanship of Thai silk production.

| graduation stole | queen size | wholesale price | 100% wool |

| designer scarf | toddler size | Wired Headband | custom design |

In conclusion, custom Thai silk production is a fascinating and intricate process that combines traditional techniques with modern innovation. Skilled artisans work tirelessly to create luxurious and unique fabrics that showcase the rich cultural heritage of Thailand. From the selection of the finest silk threads to the intricate weaving and dyeing processes, every step in the production of custom Thai silk is carefully executed to create fabrics that are truly one-of-a-kind. Whether you are looking for a custom silk handkerchief, a real silk scarf, or any other custom silk product, you can be sure that it will be crafted with the utmost care and attention to detail in a custom Thai silk factory.