Exploring the Process of Custom Thai Silk Production

Thailand is renowned for its exquisite silk production, with a long history of creating some of the finest silk fabrics in the world. Custom Thai silk factories play a crucial role in preserving this tradition and providing customers with high-quality, personalized silk products. From custom real silk scarves to silk shawls, these factories offer a wide range of options for those looking to add a touch of luxury to their wardrobe.

The process of creating custom Thai silk products begins with the selection of the raw materials. Silk is a natural fiber that is produced by silkworms, and the quality of the silk fabric depends on the quality of the cocoons used. Custom Thai silk factories source their silk from reputable suppliers who provide them with the finest silk cocoons available. These cocoons are then carefully unraveled to extract the silk threads, which are then spun into yarn.

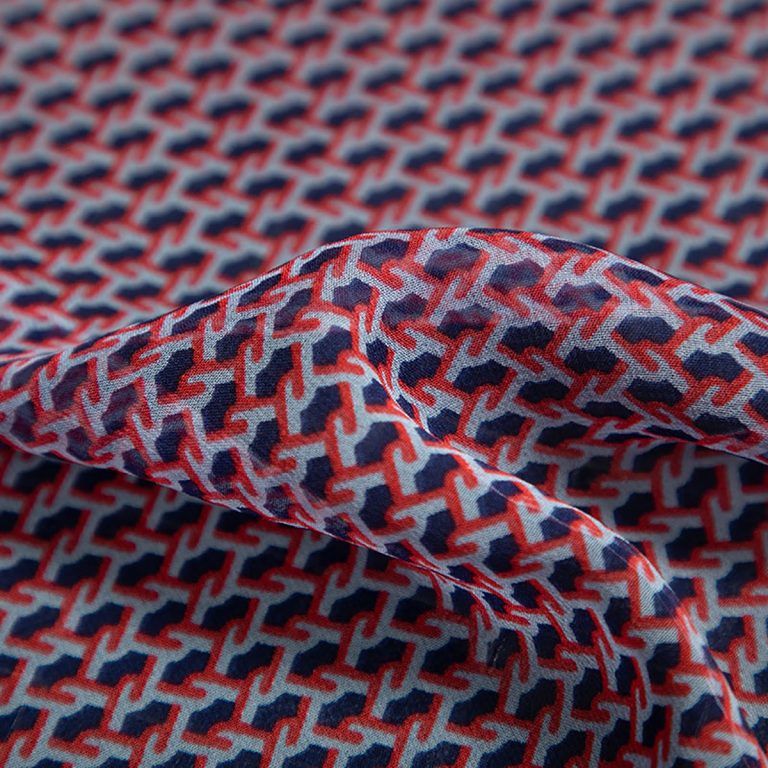

Once the silk yarn has been produced, it is dyed using a variety of natural or synthetic dyes to achieve the desired color. Custom Thai silk factories often have a team of skilled artisans who are experts in the art of dyeing silk, ensuring that the colors are vibrant and long-lasting. After the yarn has been dyed, it is ready to be woven into fabric.

The weaving process is where the magic happens, as skilled weavers use traditional looms to create intricate patterns and designs on the silk fabric. Custom Thai silk factories offer a range of weaving techniques, from simple plain weaves to more complex patterns like brocade and jacquard. Customers can choose from a variety of designs or even submit their own designs to be woven into the fabric.

Once the fabric has been woven, it is carefully inspected for any imperfections before being sent to the finishing department. Here, the fabric is washed, ironed, and treated with special finishes to enhance its luster and softness. Custom Thai silk factories take great care in ensuring that each piece of silk fabric meets their high standards of quality before it is ready to be made into a custom product.

| pipiing edge | cap shawls | a sash | satin lined hat |

| bandana neck | bandanas custom | muffler | printing reviews |

| bolero | bhldn shawl | silk Crepe De Chine | 45cm scarf |

| instant hijab | cantu scarf | hijab silk | 19momme |

Custom Thai silk factories also offer a range of customization options for customers looking to create their own unique silk products. From custom real silk scarves to silk shawls, customers can choose the size, shape, color, and design of their silk products to suit their individual style and preferences. Skilled artisans work closely with customers to bring their vision to life, creating one-of-a-kind silk products that are truly special.

In conclusion, custom Thai silk factories play a vital role in preserving the rich tradition of silk production in Thailand and providing customers with high-quality, personalized silk products. From custom real silk scarves to silk shawls, these factories offer a wide range of options for those looking to add a touch of luxury to their wardrobe. With a focus on quality, craftsmanship, and customization, custom Thai silk factories continue to be a popular choice for those seeking unique and beautiful silk products.